What are Steller Floors' patented clips made of?

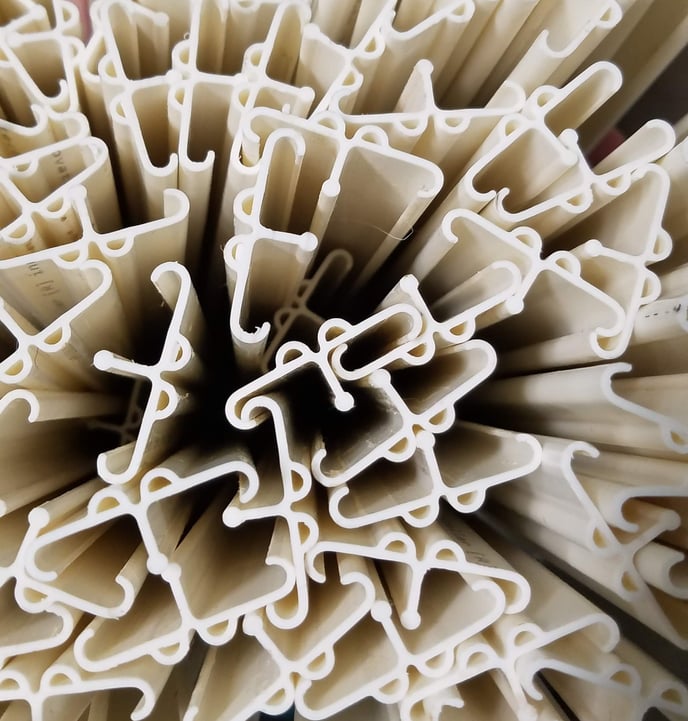

We use rigid PVC to make the most durable and long-lasting flooring clips for Steller Floors.

Steller Floors are constructed by using clips to attach plank-to-plank instead of using nails or glue to attach plank-to-subfloor. Since the clips are an important part of this construction, it is necessary to make them from the most resilient material possible. Our R & D Team did a ton of research on different polymer chemistry and finally the Plastics Research Lab at Penn State Behrend helped us choose rigid PVC.

What is rigid PVC?

Rigid PVC (or uPVC) is most commonly used in plastic drain pipes thanks to its well-known strength and durability. This material notably does not include plasticizers, which could otherwise migrate out of the material and off-gas as VOCs. While there is a substantial benefit of not having plasticizers in your flooring, it also helps to know that plasticizers won't cause your Steller clips to become brittle with age, heat, or use.

In fact, the only elements that will affect our clips are sunlight and extreme cold. Luckily, our clips are conveniently hidden underneath the floor (out of the sunlight), and our flooring tends to be used in climate controlled homes. When the clips become extremely cold, they could become brittle and simply need to warm up to room temperature before they can be used.

How long will the Steller Floors clips last?

The truth is, we don't know--but it is a really long time. We guarantee our clips for 20 years, and we reasonably expect them to last that long through typical use. "Typical use" includes all of the cases in our installation guide, but we've seen our clips perform even better. For instance, we frequently travel to tradeshows where we assemble anywhere from 200-800 sqft and remove and re-install planks repeatedly for hours and days on end for visitors to the booth. These same planks and clips function continuously under high-pressure and we are exceptionally pleased with their performance.

Are Steller Floors PVC clips bad for the planet?

As a company based on sustainability, whether our products are good for the planet or not is an important question to answer accurately! Plastics, and in particular single use plastics, have earned a negative reputation because they are used once and thrown away or incinerated. In the case of a landfill, the plastics don't degrade for millions of years, and during incineration, plastics can contribute to global warming if CO2 is released into the atmosphere or release toxins into the air. Steller Floors' clips are not single use because they can be used and re-used many times, and they can even be recycled into new clips--which keeps them out of the landfill or from being incinerated.

Additionally, our Steller Clips weigh about 0.12 lbs/sqft versus LVP 2.2 lbs per sqft, which represents a 95% reduction in plastics use--and, LVP is built to last to 5-20 years versus our floors which are built to last for 100+. Of course, traditional hardwood floors that use nails or glue do not have plastic components, but nails or glue themselves make materials harder to disassemble and shorten their material lifespans.

Obviously, this is a complex method of analysis, but in the future it is likely going to be important to build materials that last versus materials that need to be thrown away at the end of their lifecycles. For example, a recent report by the Architects Climate Action Network recommends only using reversible fasteners in wood products so that they can last as long as possible--and Steller Floors' construction complies with this recommendation.

Are there any alternatives for PVC in Steller Floors' future?

While none of us will be around to discover the planetary impact of Steller Floors' clips, we are proud of the huge effort we made to balance the competing interests of having a reliable material that could last 100+ years and can be recycled. That said, we are always researching new ways to use already-recycled plastic and bioplastics in our floors to help them become more sustainable. Hopefully in the future we will be able to offer both materials to our clients so that they can choose the option that best suits their needs and helps support the health of the planet!